Best Microscope Settings for Mobile Repair Technicians

Best Microscope Settings for Mobile Repair Technicians

🔍 Why Is a Microscope Important in Mobile Repair?

Modern smartphones use tiny SMD components and micro tracks on motherboards. Without a microscope, it’s almost impossible to repair issues like:

Jumper making on broken lines

IC reballing and soldering

Checking short components

Inspecting connector pins

Lekin microscope ka sahi focus, magnification aur lighting setup hi repair ko easy aur professional banata hai.

🛠 Recommended Microscope Types for Mobile Repair

Stereo Microscope (Binocular/Trinocular)

Most common for mobile repair

10x – 40x magnification

Clear 3D view of components

Digital Microscope (with LCD/PC output)

Good for teaching & demonstrations

Adjustable zoom (up to 1200x in some models)

Recording option for tutorials

Trinocular Microscope with Camera

Best for both working + recording

Useful for repair institutes

⚙️ Best Microscope Settings for Technicians

🔧 1. Magnification Settings

10x – 20x → For general inspection (tracks, small capacitors, resistors)

25x – 40x → For jumper wires, micro soldering, connector repair

50x+ → For deep inspection (cracks in IC pins, reballing inspection)

👉 Rule: Use the lowest magnification that gives a clear view – it reduces eye strain.

🔧 2. Focus Adjustment

Always adjust focus so that the component appears sharp and crystal clear.

Keep your working distance (between microscope lens & motherboard) comfortable – around 10cm is ideal for soldering.

🔧 3. Lighting Settings

LED Ring Light is best → Provides even light without shadows.

Adjust brightness according to surface reflection.

For shiny ICs or solder balls → Use slightly angled lighting to avoid glare.

🔧 4. Camera/Display Settings (if using Digital Microscope)

Resolution: 1080p minimum for clear recording.

Frame rate: 30–60 FPS for smooth video.

Brightness/Contrast: Adjust to highlight tiny solder joints.

⚡ Pro Tips for Using Microscope in Mobile Repair

Keep your eyes 2–3 cm away from eyepiece to reduce strain.

Always secure motherboard on a PCB holder for stable view.

Use anti-glare lens covers if you work long hours.

If doing reballing → magnification around 35x is most comfortable.

Clean the microscope lenses regularly with microfiber cloth.

✅ Benefits of Correct Microscope Settings

Precision in micro soldering

Faster repair time

Reduced mistakes on fine components

Less eye fatigue for technicians

Professional results for customers

📌 Meta Description (SEO)

Best Microscope Settings for Mobile Repair Technicians explained. Learn ideal magnification, focus, lighting, and pro tips to make micro soldering and board repairs easier.

🔖 Tags (Ready-to-Paste)

best microscope settings, microscope for mobile repair, mobile repairing microscope guide, microscope magnification soldering, mobile repair tools, trinocular microscope setup, digital microscope mobile repair, soldering under microscope

👉 Jani, yeh guide technicians aur students dono ke liye bohot kaam ki hai.

Kya chahte ho mai agli baar likhun “How to Use DC Power Supply in Mobile Repairing – Complete Guide”?

You said:

Ab is pr likhy

Importance of Oscilloscope in Mobile Repair

ChatGPT said:

Shandar topic jani 🔥

Oscilloscope ka use har advanced mobile repair technician ko ana chahiye, warna motherboard level kaafi issues samajhna mushkil hojata hai. Chalo detail aur professional guide likhte hain:

Importance of Oscilloscope in Mobile Repair ⚡📱

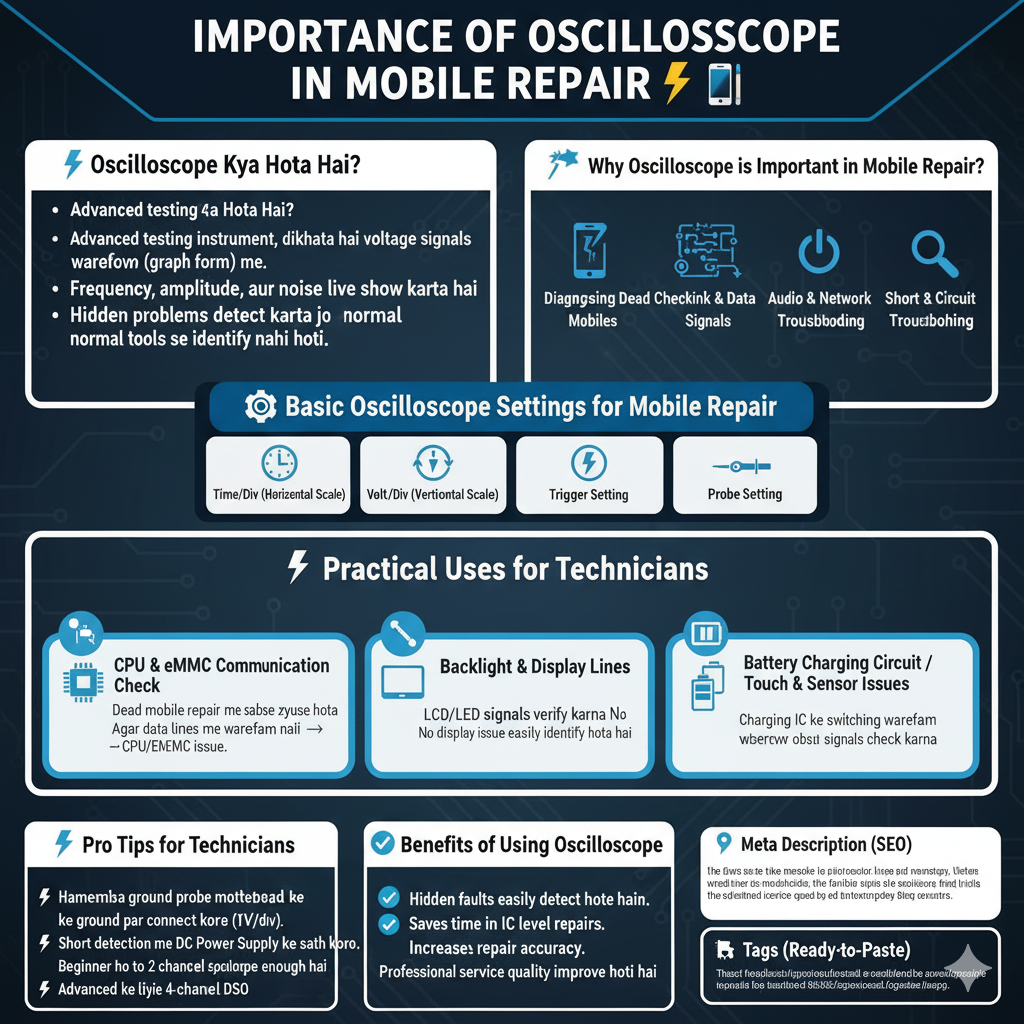

🔍 Oscilloscope Kya Hota Hai?

Oscilloscope ek advanced testing instrument hai jo voltage signals ko waveform (graph form) me dikhata hai. Simple multimeter sirf voltage, resistance ya continuity batata hai, lekin oscilloscope signal ka behavior live show karta hai – jaise frequency, amplitude, aur noise.

Mobile repairing me, ye tool hidden problems detect karne ke liye best hai jo normal tools se identify nahi hoti.

🛠 Why Oscilloscope is Important in Mobile Repair?

Diagnosing Dead Mobiles

Boot sequence signals check karne ke liye.

CPU aur eMMC ke communication signals dekhne ke liye.

Checking Clock & Data Signals

Crystal oscillator ka waveform verify karna.

I2C, SPI, aur UART data signals inspect karna.

Power IC Testing

Output rails (1.8V, 2.8V, 3.7V etc.) ke stability & ripple check karna.

Agar line noisy ho to mobile boot issue create hota hai.

Audio & Network Troubleshooting

Audio IC me signals verify karna.

RF/Network circuits me waveform dekhna.

Short Circuit Analysis

PCB par unusual waveforms trace karke faulty component identify karna.

⚙️ Basic Oscilloscope Settings for Mobile Repair

Time/Div (Horizontal Scale): Adjust to capture signal speed (e.g., fast clock signals need smaller scale).

Volt/Div (Vertical Scale): Adjust according to signal level (1V, 3.3V etc.).

Trigger Setting: Stable waveform ke liye proper trigger set karna.

Probe Setting: Use x10 probe for motherboard testing (better accuracy).

🔧 Practical Uses for Technicians

CPU & eMMC Communication Check

Dead mobile repair me sabse zyada use hota hai.

Agar data lines me waveform nahi → CPU/eMMC issue.

Backlight & Display Lines

LCD/LED signals verify karna.

No display issue easily identify hota hai.

Battery Charging Circuit

Charging IC ke switching waveform observe karna.

Touch & Sensor Issues

Capacitive touch signals check karna.

⚡ Pro Tips

Hamesha ground probe motherboard ke ground par connect karo.

Start with low voltage scale (1V/div) aur gradually increase karo.

Short detection me oscilloscope ko DC Power Supply ke sath use karna bohot effective hai.

Agar beginner ho, to 2-channel oscilloscope enough hai.

Advanced repair shops ke liye 4-channel digital storage oscilloscope (DSO) recommended hai.

✅ Benefits of Using Oscilloscope

Hidden faults easily detect hote hain.

Saves time in dead mobile & IC level repairs.

Increases repair accuracy & success rate.

Professional service quality improve hoti hai.

Customer trust barhta hai jab aap advanced tools use karte ho.

Meta Description

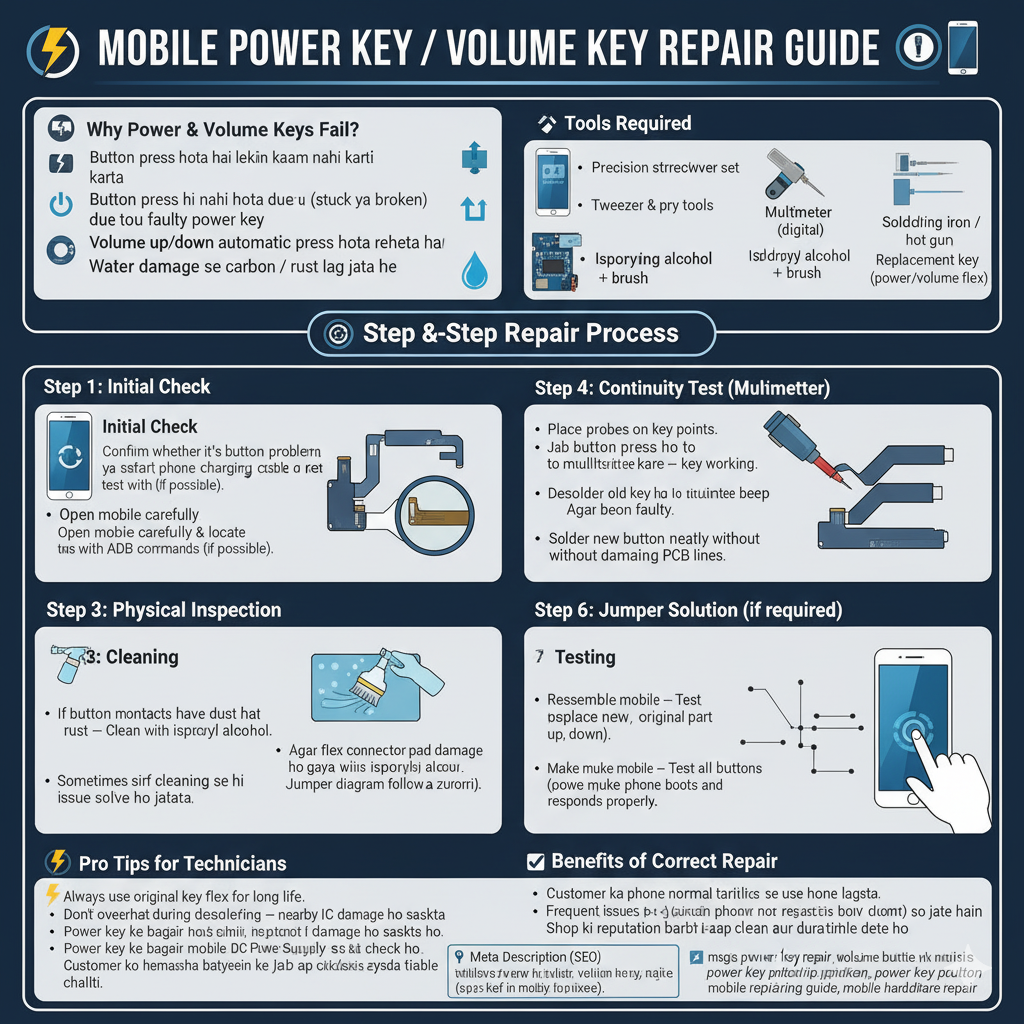

Mobile Power Key / Volume Key Repair Guide. Learn easy step-by-step process to clean, test, replace, or jumper faulty keys in mobile phones.

Tags

mobile power key repair, volume button not working, mobile key jumper, power key solution, volume key problem, power button replacement, mobile repairing guide, mobile hardware repair